Since the available analytical methods for the analysis and characterization of materials are beset by technical problems due to the viscosity of materials such as polymers (plastics), pharmaceuticals and paint; the inverse gas chromatography (IGC) method (sometimes called the molecular probe technique) eliminates these difficulties.

Gas Chromatography versus Inverse Gas Chromatography

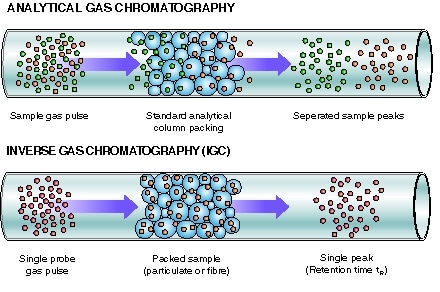

Gas chromatography (GC) is a common type of chromatography used for decades in analytical chemistry for separating or analyzing compounds, and the quantification of a mixture of components that can be injected into a column by vaporizing the mixture without decomposition under thermal conditions. Typical uses of GC include testing the purity of a substance or separating the different components of a mixture (the relative amounts of such components can also be determined). In some situations, GC may help in identifying a compound. In preparative chromatography, GC can be used to prepare pure compounds from a mixture. The focus of the GC method is on the mixture injected into the column without knowing the physio-chemical properties of the column itself.

Inverse Gas Chromatography (IGC) is a physical characterization analytical method that is used to study the physio-chemical properties of polymers coated onto the chromatographic column and analyze the surfaces of polymer solids to obtain a wealth of information on the column itself, as opposed to the mixture injected. It uses the injection of a pure standard solute with known properties into the injection port and monitors its interaction with the polymer coated onto the chromatographic column. A single gas or vapor (probe molecule) is injected into a column packed with the solid sample under investigation. It is an alternative analytical technique that complements the conventional analytical techniques and replaces those that cannot handle the analysis of viscous materials. IGC is considered a materials characterization technique.

(Adapted from https://www.azom.com/article.aspx?ArticleID=11831)

Description of IGC

A polymer or any material that can be packed in a column, is studied in the solid phase under conditions which can be made to approximate conditions of use, or processing and fabrication. GC equipment is relatively cheap and easy to operate which makes it possible to collect large amounts of data. GC is becoming the method of choice for the study of thermodynamic interaction of small molecules (solvents) with high molar mass materials in the solid phase. Since the stationary phase, which contains the polymer or materials, is under study (unlike the conventional GC method), the GC method is re-named as Inverse Gas Chromatography (IGC). The information is obtained on the stationary phase rather than on the separation of the injected mixture.

IGC Analysis Versus the Traditional GC

Researchers have contributed to the development and the promotion of the IGC method since the early 1970's by applying it to complex polymeric systems, resulting in several thousand publications from labs around the world. (A brief summary of this literature is given in the reference section of this website.) The chromatographic data produced by the IGC experiment is further analyzed to yield the desired thermodynamic properties on the materials in question.

Determining whether a certain material is a viable component to end products is currently a time consuming experience that requires hours of research, manual calculations and tests. Unfortunately, other than identifying the chromatographic peaks emphasizing the separation of a mixture, current gas chromatograph tools do not supply tailored software focused on the thermodynamic analysis. Industry is in need of a much faster and cheaper way to obtain data on thermodynamic properties that provides a material’s affinity and strength of interaction with solvents and/or other materials. POLYSIS was specifically developed to fill this need in the marketplace. It is the only software application that is able to measure the strength of interaction of solvents with materials and the interaction of a more complex system when two materials are blended with each other (known as an alloy or blend).

Competing alternatives to IGC such as vapor sorption method, which takes hours or even days to establish the equilibrium between materials and solvents, delays the production of final data. POLYSIS provides a faster technique by utilizing IGC data that can be inputted manually into the software. Further, POLYSIS automates the data obtained from IGC and creates final reports and allows the end user to easily export the results to Excel spreadsheets, copy to notebook and or/email the report.

POLYSIS:Software for Thermodynamic Chemical Analysis of Materials

Some content on this page is saved in PDF format. To view these files, download Adobe Acrobat Reader free. If you are having trouble reading a document, request an accessible copy of the PDF or Word Document.